[ CNC Controller ]

CC / 2001

Final Assembly of the Controller

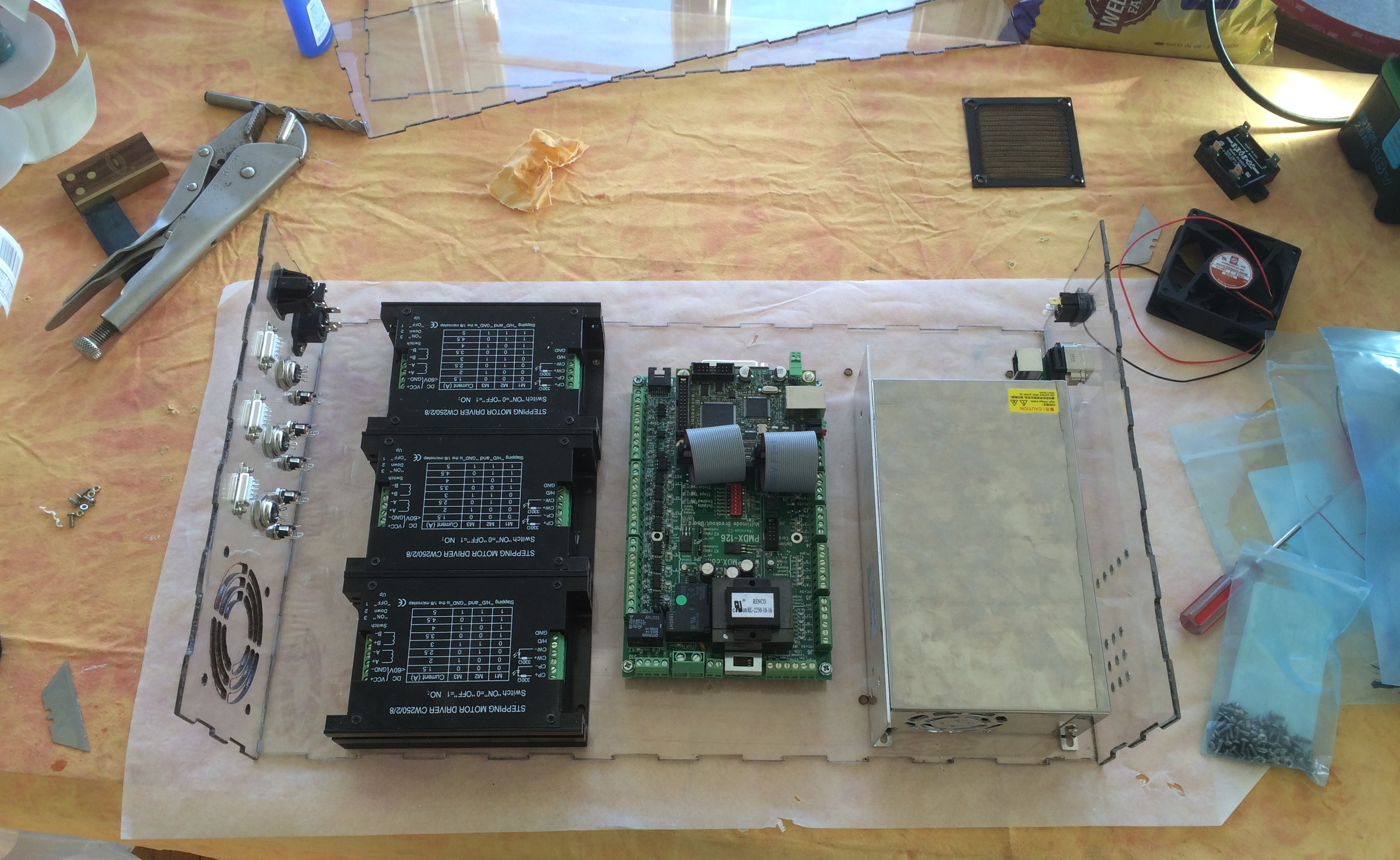

This CNC controller is a three-axis stepper motor driver controlled over Ethernet. With a custom laser-cut case, the controller houses a PMDX-126 and an Ethernet SmoothStepper and is compatible with CNC control software like Mach 4.

This controller was my high school senior design project, a culmination of skills and tools I learned to use in the Fab Lab I helped create. This space began my journey and laid the foundation for my current trajectory. In reality, this page is less about the controller itself, simple as it is, and more a place for me to tell a quick story about a pivotal time in my life.

When I was a sophomore in high school, I took a class called Digital Media which was my introduction to the room that later became the Tech Shop. It was also Bob Valli’s first year teaching. Bob is an educator of the best variety. If you have a vision, he gives you the tools to make it happen.

In the room there was an old 3D printer, a commercial spin-off of the original Darwin RepRap called the RapMan. The display was broken and the extruder wasn’t working correctly. Bob wasn’t sure what the machine was and gave me full reign to mess around with it. Over the next few weeks, I read everything I could find including old manuals and 3D printing tutorials. Slowly, the printer came to life, whirring musically and printing basic shapes.

For the rest of high school, I went to the shop every single day. I repaired and restored plasma cutters, lathes, old mills, and an old Frasca 141 flight simulator from the early 90s. As more people started to use the equipment we fixed, we got budgets for newer supplies. New 3D printers, laser cutters, additional flight simulators for ground school classes, and CNC routers became part of the growing Fab Lab. I set up, learned how to use, and began teaching others about each machine. The Fab Lab became my second home, full of late nights, homework, and tools.

I can tie almost all of my foundational knowledge to that space and period of time. I gained a skillset I never knew I’d have and a passion for making things that I know I’ll never lose.